ABOUT US

We turn ideas into thoughtful design and purposeful execution.

Where Imagination Meets Stone

Established in 1978 at Kishangarh, Rajasthan, Bhutra Marble stands as a pioneer in the world of natural stone. From raw marble blocks to breathtaking architectural creations, we bridge art and architecture — crafting surfaces that reflect elegance, innovation, and emotion.

Why You Choose Bhutra Marble For Your Marble Needs?

When it comes to choosing a supplier for your marble and granite needs, Bhutra Marble is the best choice. Here are just a few reasons why:

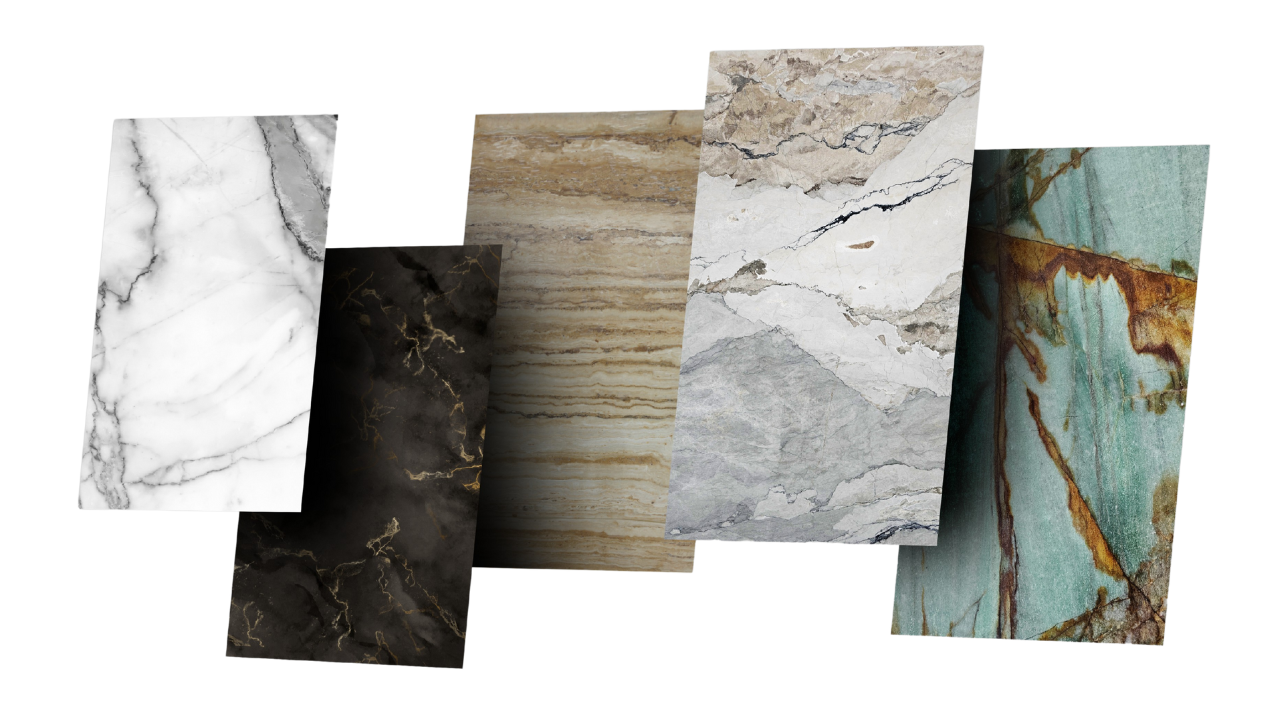

- Wide selection: Bhutra Marble has an extensive selection of marble and granite options to choose from, including popular choices like any types of marble(Italian and Imported, white marble), Sand Stone, Travertine, Onyx, Quartzite and much much more. No matter what look you’re going for, you’ll find the perfect stone at Bhutra Marble.

- High-quality materials: Bhutra Marble only sources the finest quality marble, ensuring that you’re getting the best value for your money. Each stone is carefully inspected for consistency, color, and overall quality.

- Competitive pricing: Bhutra Marble offers competitive pricing on all of its marble options, making it easy to find the perfect stone within your budget.

- Expert guidance: The team at Bhutra Marble is made up of experts who are knowledgeable about all aspects of marble. They can provide helpful guidance and advice on which stone is best for your project, as well as assist with installation and maintenance.

- Excellent customer service: At Bhutra Marble, customer satisfaction is a top priority. The team is dedicated to providing exceptional customer service, ensuring that you have a positive experience from start to finish.

With its wide selection, high-quality materials, competitive pricing, expert guidance, and excellent customer service, Bhutra Marble Pvt. Ltd. is the clear choice for all of your marble and granite needs.

Our Purpose

[ The principles shaping our vision, mission, and values ]

To be a globally recognized leader in the marble industry, supplying premium, high-quality stone. We will expand our product range and geographic reach to meet global construction and remodeling demand.

OUR VALUES

The standards we don’t compromise

view details ➝

To meet customer needs by transforming natural stone into high-quality marble and granite that deliver beauty and lasting value. We adhere to international quality standards while driving innovation, strengthening local industry, and expanding our global presence.

OUR MISSION

What we deliver every day

view details ➝

Our core values are customer-first commitment, integrity and loyalty, fair-priced quality materials, an exceptional product range, and a culture of equality and team empowerment.

OUR VALUES

The standards we don’t compromise

view details ➝

Defined by Quality. Trusted Worldwide.

Full customer satisfaction is our core principle. That is why, we work hard to adapt our systems to change as per customer’s requirement and realize their expectations, without compromising from any detail. A flawless production process and timely deliveries are the main constituents of our policy on quality.

We conduct customer briefings on our product ranges, along with flawless production and timely deliveries. We adopt on-going improvement in all our business aspects and prospects, rather than maintenance of our existing conditions, as our fundamental philosophy. We organize and hold on-going training instructions for the qualification of our staff. We arrange for the best quality at optimum price with our suppliers of raw materials. Our brand symbolizes our quality and this is the signature we set for the future.

The endeavor of the company is to provide quality products in huge variety of colors with sharp finishing and cuts making it distinct from others. For this the company has employed skilled purchasers who understand the need and taste of architects, interiors and more. Quality control engineers have also been employed to maintain a strict vigil on the quality of the products. All the products have inspection reports and test certificates to avoid any defects.

Infrastructure

End-to-end control from source to shipment.

Where Innovation Meets Craftsmanship in Every Slab

Step 1 – Extraction of Marble Blocks

Stone is found naturally in large rock masses, and the extraction process is known as quarrying. From our rich deposits of White Marble, Green Marble, and other premium stones, we carefully extract solid marble and granite blocks. Using advanced techniques like diamond cutting, drilling, and controlled blasting, massive bench walls are separated and processed into uniform blocks—each weighing up to 25,000 pounds—ready for precision finishing.

Step 2 – Process Before Block Cutting

After extraction, the marble and granite blocks undergo precise processing to suit their final application. Before moving forward, each block is carefully graded based on size, color tone, streak patterns, cleanliness, and the presence of cracks. Better clarity and fewer streaks mean higher quality. Because of their massive weight and dimensions, every block is handled with specialized cranes and advanced machinery during movement, loading, and further processing—ensuring safety, accuracy, and structural integrity.

Step 3 – Block Cutting

Marble blocks are cut into usable slabs using advanced diamond wire systems and gang saw machines. Depending on block size, large blocks are processed with multi-wire cutters while smaller or irregular blocks are shaped using block cutters to minimize waste and maximize usable material. Multiwire machines produce full-sized slabs, whereas block cutters create strips that are later refined through precision cutting equipment to form perfectly measured tiles for construction and design use.

Step 4 – Fabrication & Polishing Of Stone Slabs

After cutting, the slabs move to the production line for strengthening and finishing. First, a reinforcing mesh is applied to enhance durability. Then the stone undergoes finishing treatments to achieve the desired look and texture. These include polishing for a glossy shine, honing for a smooth matte surface, ageing for a naturally worn effect, bush hammering for a rough anti-slip finish, sanding for a softer texture, and split-face for a rugged, rustic appearance. At this stage, slabs are either ready for sale or proceed for further cutting and specialized finishing based on project requirements.

Step 5 – After Finishing, Stone Slabs ready for Display

Once the final finish is completed, the slabs are either displayed or securely packed for dispatch. For international shipping, slabs are carefully placed in wooden crates and loaded into containers, while domestic shipments are transported using strong iron A-frames to keep them stable. Tiles are packed separately in wooden boxes to ensure safe handling and delivery.

Step 6 – Stone Installation for Royal look to Interiors

Marble brings timeless luxury to interiors with its elegant veining, rich appearance, and long-lasting strength. From floors and bathrooms to countertops and backsplashes, it delivers a refined, premium look while remaining easy to maintain with occasional cleaning and polishing. Its sophisticated finish enhances modern living spaces, perfectly balancing comfort, style, and design excellence.

Stone is found naturally in large rock masses, and the extraction process is known as quarrying. From our rich deposits of White Marble, Green Marble, and other premium stones, we carefully extract solid marble and granite blocks. Using advanced techniques like diamond cutting, drilling, and controlled blasting, massive bench walls are separated and processed into uniform blocks—each weighing up to 25,000 pounds—ready for precision finishing.

After extraction, the marble and granite blocks undergo precise processing to suit their final application. Before moving forward, each block is carefully graded based on size, color tone, streak patterns, cleanliness, and the presence of cracks. Better clarity and fewer streaks mean higher quality. Because of their massive weight and dimensions, every block is handled with specialized cranes and advanced machinery during movement, loading, and further processing—ensuring safety, accuracy, and structural integrity.

Marble blocks are cut into usable slabs using advanced diamond wire systems and gang saw machines. Depending on block size, large blocks are processed with multi-wire cutters while smaller or irregular blocks are shaped using block cutters to minimize waste and maximize usable material. Multiwire machines produce full-sized slabs, whereas block cutters create strips that are later refined through precision cutting equipment to form perfectly measured tiles for construction and design use.

After cutting, the slabs move to the production line for strengthening and finishing. First, a reinforcing mesh is applied to enhance durability. Then the stone undergoes finishing treatments to achieve the desired look and texture. These include polishing for a glossy shine, honing for a smooth matte surface, ageing for a naturally worn effect, bush hammering for a rough anti-slip finish, sanding for a softer texture, and split-face for a rugged, rustic appearance. At this stage, slabs are either ready for sale or proceed for further cutting and specialized finishing based on project requirements.

Once the final finish is completed, the slabs are either displayed or securely packed for dispatch. For international shipping, slabs are carefully placed in wooden crates and loaded into containers, while domestic shipments are transported using strong iron A-frames to keep them stable. Tiles are packed separately in wooden boxes to ensure safe handling and delivery.

Marble brings timeless luxury to interiors with its elegant veining, rich appearance, and long-lasting strength. From floors and bathrooms to countertops and backsplashes, it delivers a refined, premium look while remaining easy to maintain with occasional cleaning and polishing. Its sophisticated finish enhances modern living spaces, perfectly balancing comfort, style, and design excellence.

What People Say

Trustindex verifies that the original source of the review is Google. Good quality best rate super sarvice 👌Posted onTrustindex verifies that the original source of the review is Google. Visited Bhutra marbel in kishangarh after exploring the whole market . Meet with satyapal bhaiya for marbel selection ,he is gem of a person . Moreover they have a large variety of marbles.Very happy with the prices and quality of the marbelPosted onTrustindex verifies that the original source of the review is Google. Good with product and good with hospitality,Posted onTrustindex verifies that the original source of the review is Google. bhutra has been a overwhelming experience, we came here not having much expectations due to the confusion other dealers created amongst us . but the people in bhutra took our expectations through the roof. their hospitality and their way of explaining the things even to the finest details has helped us a lot therefore i would highly recommend anyone who comes to kishangarh to buy marbles to visit this place . it is very well worth it :)Posted onTrustindex verifies that the original source of the review is Google. I am from banglore , i have to to rajasthan kishangarh to purchase marbles from Bhutra it's is good quality and good experience they have good marbles 👍👍👍Posted onTrustindex verifies that the original source of the review is Google. Good pricePosted onTrustindex verifies that the original source of the review is Google. We had a great experience with Bhutra Marbles, Kishangarh. Mr. Serveshver Sir (Owner) personally guided us and is a very genuine, humble, and knowledgeable person. Special thanks to Deepak (Sales) for his excellent support, patience, and clear guidance throughout the selection process. The quality of marbles is excellent, and the service is honest and professional. Highly recommended for anyone looking for premium marbles with trustworthy service.Posted onTrustindex verifies that the original source of the review is Google. Good quality Good price very good staff 🤩Posted onTrustindex verifies that the original source of the review is Google. We are from Bangalore and wanted the best imported marbles for our under-construction house, which led us to visit Bhutra, Kishangarh last month which had excellent collection of marbles and granite with a wide range of designs. Every item stands out, making it hard to choose as each one is better than the next and excellent quality, the pricing was so good that we ended up buying marble for our entire house. The hospitality was warm and welcoming, Bhutra brothers were so friendly and supportive, making the entire experience truly pleasant. Would strongly recommend Bhutra for best quality marbles.